Drive Systems

Drives must match your requirements - not the other way around. So that your system can use its full potential, we will support you with a tailor-made drive system. Leave the technical details to us: we will plan, manufacture, install and maintain your motor systems for you.

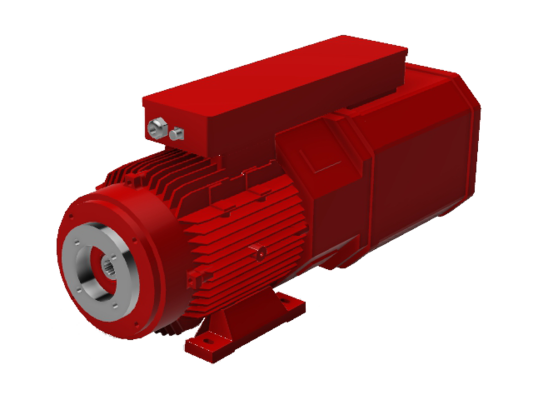

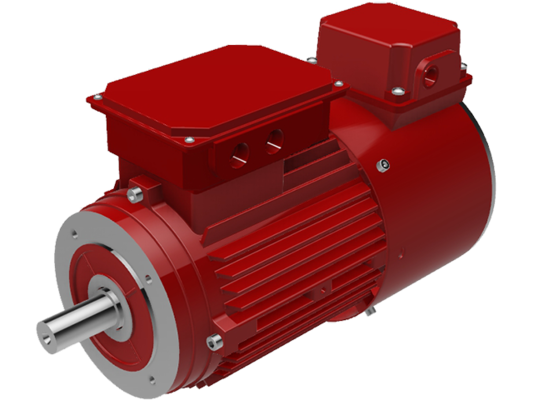

Asynchronous motors

Fits in anywhere

Whether as a ventilator drive, extruder drive, tooled machine drive or vehicle drive: our asynchronous drives are universally usable, simple to handle and economical to operate.

Wherever you need consistent performance, robust construction and high capacity, our asynchronous drives are the perfect solution. The purely asynchronous variant delivers consistently precise RPMs, and the asynchronous servo motor demonstrates excellent controllability. Beyond this, both variants defy mechanical loads, can be used in areas at risk of explosion, and can handle severe overloading for short times.

In technical terms, the three-phase asynchronous machine consists of an inner, passive rotary piston and an external engine block. In the air gap between the block and the rotor, the rotary field is at work and determines the RPM and the torque. There are no brushes or commutator in this construction. It is considered to be the world’s most-used electric motor.

Let us advise you! We will build you a quality drive system that fits precisely, is simple to handle, economical to operate, and flexible in its application. Three-phase asynchronous motors are among the most economical, if there is no particular requirement for compactness of size.

Advantages

- Universal application

- High level of effectiveness

- Consistent performance

- Robust construction

- Long life

- Low maintenance

- Economical to operate

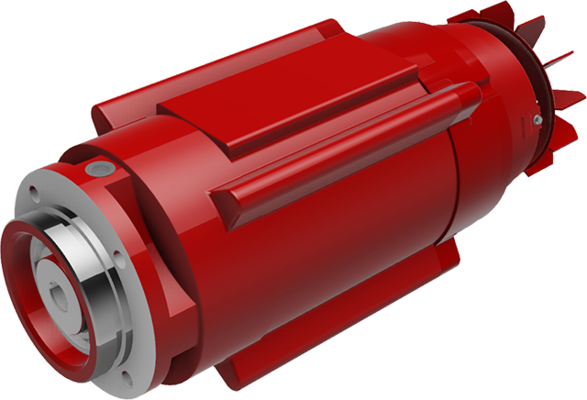

Generators

Your personal power station

Our generators deliver your power with a high level of effectiveness via asynchronous or synchronous technology. They work constantly and reliably in a huge range of situations and conditions, including underwater.

Advantages

- High level of effectiveness

- Reliable even in constant operation

- Can also be used underwater

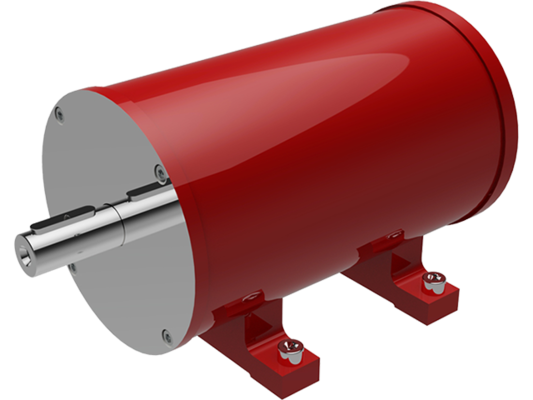

DC motors

Simple and compact

Whether as pitch drives in wind energy farms, wrapping drives in the textile industry, or drives for presses and cutters: DC drives play to their advantages in these systems and represent good pricing as well as high quality for solutions in multiple industries.

DC drives are compact and easy to handle. They can be used in many ways, primarily due to the stability of their RPM, their excellent start-up and braking times, and their large adjustment range.

From a technical point of view, their linear control behaviour combined with simple conversion of three-phase current to DC leads to a compact structure. According to your requirements, the drive is calibrated to one of the following: extremely stable RPM (shunt motor), high tightening torque (serially connected motor), or an optimum combination of both advantages (twin connection motor). Permanently excited DC drives also avoid excitation windings and therefore offer an even higher level of effectiveness.

Simply give us your requirements and you will receive a tailor-made solution optimised to your application situation, that will do its job reliably.

Advantages

- Compact structure

- Very good controllability qualities

- Stable RPMs

- High capacities

- Very good concentricity qualities

- Very low maintenance

- User-friendly operation

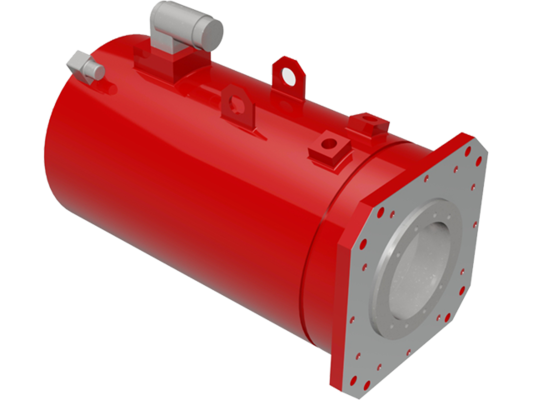

Hollow shaft servo motors

Precise and powerful

Whether in extruders, presses, cutters or pumps: our hollow shaft servo motors are economical to operate, flexible in their design, and are always used when large loads are to be moved at different speeds.

Our hollow shaft drives come out on top when you need precision and power in linear movement. The highly dynamic and precise positioning control facilitates a high level of repeatability precision, while the compact construction combined with the system’s high rigidity ensures low inertia and high performance data. Performance can be increased even more if liquid cooling is used instead of air cooling. This is because the lower mass of liquid-cooled motors means they have higher dynamics that can be used for even shorter cycling times. Additionally, the drive can be constructed in many ways to suit its task: for example, in the case of a short stroke, a motor with a blind hole is the perfect solution, whereas in the case of an unlimited stroke, drives with a continuous hollow shaft would be used.

In technical terms, hollow shaft servo motors are fast-running direct drives.

Your requirements are the basis for a tailor-made, high-performance and yet economically-priced solution. Replace your existing hydraulic or pneumatic drives and profit from higher energy efficiency, virtually maintenance-free operation, and extremely good controllability.

Advantages

- High acceleration

- High dynamics

- High drive rigidity, no radial clearance

- High precision

- Almost maintenance-free, high availability

- Compact structure

- High level of effectiveness and high efficiency

Low voltage vehicle drive

Indispensable in underfloor vehicles

Whether as a drive for forklifts, ice machines, coaches or electric carts. Our low-voltage motors, between 12 and 80 volts AC, can be used with open loops or closed loops and with squirrel-cage rotors or magnet rotors, anywhere a robust drive is needed.

Advantages

- High acceleration

- High dynamics

- Almost maintenance-free, high availability

- Compact structure

- High level of effectiveness and high efficiency

- High protection class

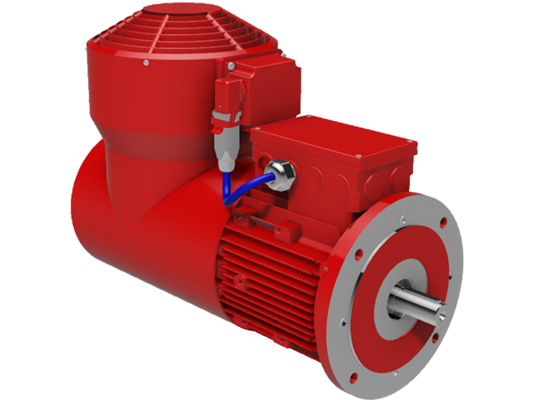

Synchronous motors

Always in rhythm

Whether as a drive for conveyor belts in the grocery industry or as axle drives in tooled machine construction or automation technology: our synchronous drives shine with an extremely high level of effectiveness and when arranged in a group, they run in absolute synchronicity.

Our synchronous drives can be built compactly because they have low rotary inertia. This facilitates highly dynamic applications with short cycles and high accelerations. Due to their energy-efficient operation and construction-based synchronicity, they are also predestined for constant operation.

From a technical point of view, synchronous drives are three-phase machines whose rotor runs in perfect synchronicity with the rotational field. They require an excitation field, are constructed as integrated or rotating field machines, and can be used for reactive power compensation.

Do you need a drive with a consistent RPM or a motor for highly dynamic applications? We will be glad to construct your personal synchronous drive. Just contact us!

Advantages

- Very high level of effectiveness

- Very energy efficient

- High level of power density

- Low rotary inertia

- Compact structure

- Low maintenance

- Precise frequency of RPMs

Torque motors

High performance in the smallest of spaces

Our torque motors, developed personally according to your requirements, will show off their strengths for you. Applied directly to the load, optimised for high torques, and set within a compact structure, the strong performance of our drives is impressive. Thanks to high acceleration, high dynamics, and high rigidity, they are ideal for use in rotary and linear movements. Compared with ordinary motors, their improved controllability leads to increased precision in repeatability. Our direct drives have no gears, are low on wear and tear, and score with a high level of effectiveness.

Technically speaking, torque motors are multi-pole direct drives, mostly constructed as brushless DC motors. They gain their high torque from the combination of multiple poles, large diameter and external rotor.

Replace your old gear motor with a torque motor tailored to your needs. This will allow you to profit from a lower maintenance effort, lower space requirements and lower energy use. Of course we will construct your drive according to your exact wishes: as an assembly kit or inside a housing, as an external or internal motor, with or without a hollow shaft.

Advantages

- High acceleration

- High dynamics

- High drive rigidity, no radial clearance

- Very good precision for positioning and repeatability

- No parts subject to wear, virtually maintenance-free, and long life

- Compact structure

- High level of effectiveness and high efficiency

- Very smooth running, zero backlash